Foreword

Welcome to my Kiribati 36 DIY build journey. A 36′ Aluminium ‘Bluewater’ sailboat with twin rudders and a retractable keel. After completing a global circumnavigation on two wheels (See: Blog | YouTube) I now set my sights on doing the same by water. My hope is that the build, cost tracking and lessons learned will aid aspiring boat builders in their own quest. Please know the following:

- I have no affiliation with the company selling the boat plans, in other words, my words are my own. I am however affiliated with Google AdWords in the hope that any revenue made will assist towards the completion of this project.

- In the event of me deviating from the original build plans, adding my own parts, or amending parts then this is highlighted in the articles with ‘** Note‘.

- An up-to-date parts/article Index (including total expenditure) can be found: HERE

- Feel free to ask question via this blog, YouTube comments, or email: kiribati36 @ modularhippo.com – My aim is to respond to all questions within 24 hours.

Cost To Date: £3,002.11->£3,158.85 | $3,492.44->$3,669.72

Index

| Build Progress | Cost Tracking | Lessons Learned | Related Links |

Build Progress

Eager to start the project I decided to begin with some parts that had to be bought (nothing that I would be able to manufacture myself).

Cost Tracking

Total Cost Chronological Order:

| 6 | PARTS/MATERIAL | EXTERNAL LABOUR | TOOLS & MISC. | TOTAL |

| (GBP) | £156.74 | £0 | £0 | £156.74 |

| (USD) | $177.28 | $0 | $0 | $177.28 |

Breakdown (when applicable):

Parts/Material – Any raw material that I needed, or any ready made parts.

External Labour – External help with machining, milling or welding.

Tools & Misc. – Cost related to project, but not part of physical boat itself.

Category Breakdown – Cost Tracking per Category in £|$|%.

| PARTS/MATERIAL | (GBP) | (USD) |

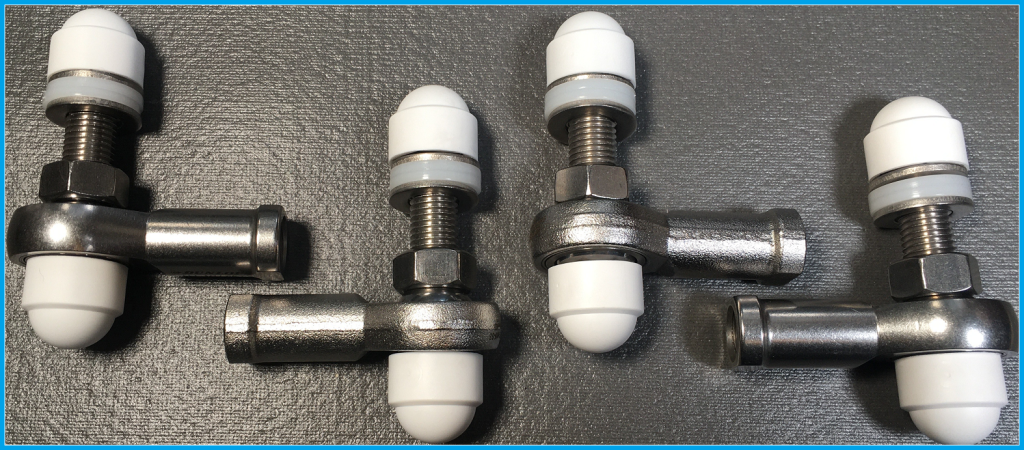

| 4 x M16 A4 Stainless Steel PTFE Liner Female Rod End Bearing. | £119.00 | (≈$134.59) |

| 4 x M16 Stainless Steel A4 Nylon Insert Nut. | £6.51 | (≈$7.37) |

| 8 x M16 White Plastic Dome Nut Protection Cap Covers. | £3.35 | (≈$3.78) |

| 8 x M16 Nylon Flat Washer – DIN 125A. | £3.19 | (≈$3.61) |

| 4 x M16 Full Nut A4 Stainless Steel DIN 934 Hexagon. | £4.08 | (≈$4.61) |

| 4 x M16 A4 Stainless Fully Threaded 75mm fully threaded Bolts. | £15.99 | (≈$18.09) |

| 8 x A4 Marine Grade 3mm M16 Washers. | £4.62 | (≈$5.23) |

| (Part 6) | Spherical Rod Ends | £156.74 | (≈$177.28) |

| CATEGORY | (GBP) | (USD) | % |

| PARTS/MATERIAL | £156.74 | (≈$177.28) | 100% |

| EXTERNAL LABOUR | £0 | $0 | 0% |

| TOOLS & MISC. | £0 | $0 | 0% |

| TOTAL | £156.74 | (≈$177.28) | 100% |

Lessons Learned

Lessons I learnt during this stage:

- SS A2 & SS A4 – Stainless Steel comes in two types A2 & A4. A2 stainless is the most common type of steel used for the manufacture of fasteners and is suitable for general use. A4 Stainless is often referred to as 316 or 18/10 stainless. As in A2 above, the numbers 18/10 refer to the chromium and nickel content- 18% chromium and 10% nickel. A4 stainless is often used in marine or chemical environments as it has greater corrosion resistance than A2. Needless to say that I opted for A4 in all my components and will be doing so going forward.

- Avoid Galvanic Corrosion at all cost – (dissimilar-metal corrosion) is an electrochemical process in which one metal corrodes preferentially, when in electrical contact with a different type of metal, and both metals are immersed in an electrolyte such as water. In my case I have made sure that I am using 3mm thick ‘Nylon’ washers to separate the different metals wherever possible.

- Marine Adhesive Sealant – As and when I come to permanently fix the components, to avoid Galvanic Corrosion in places where I cannot separate metals with a washer or similar it is highly recommended to use a Marine Adhesive sealant. This could be on Stainless Steel threads that is in contact with an aluminium connection as an example. I will personally use ‘Sikaflex 291i SIKA 291 Marine Adhesive Sealant S291WH’ after reading up on it’s reviews. I am sure that there are many alternatives, and some probably less pricey so it is definitely worth shopping around.

- Patience – The female Rod End Bearings I bought were a bit overpriced and I am sure I could have found a better price for them. I guess patience and research is key in this area.

Related Links