Foreword

Welcome to my Kiribati 36 DIY build journey. A 36′ Aluminium ‘Bluewater’ sailboat with twin rudders and a retractable keel. After completing a global circumnavigation on two wheels (See: Blog | YouTube) I now set my sights on doing the same by water. My hope is that the build, cost tracking and lessons learned will aid aspiring boat builders in their own quest. Please know the following:

- I have no affiliation with the company selling the boat plans, in other words, my words are my own. I am however affiliated with Google AdWords in the hope that any revenue made will assist towards the completion of this project.

- In the event of me deviating from the original build plans, adding my own parts, or amending parts then this is highlighted in the articles with ‘** Note‘.

- An up-to-date parts/article Index (including total expenditure) can be found: HERE

- Feel free to ask question via this blog, YouTube comments, or email: kiribati36 @ modularhippo.com – My aim is to respond to all questions within 24 hours.

Cost To Date: £2,356.25->£2547.43 | $2,719.91->$2952.78

Index

Build Progress

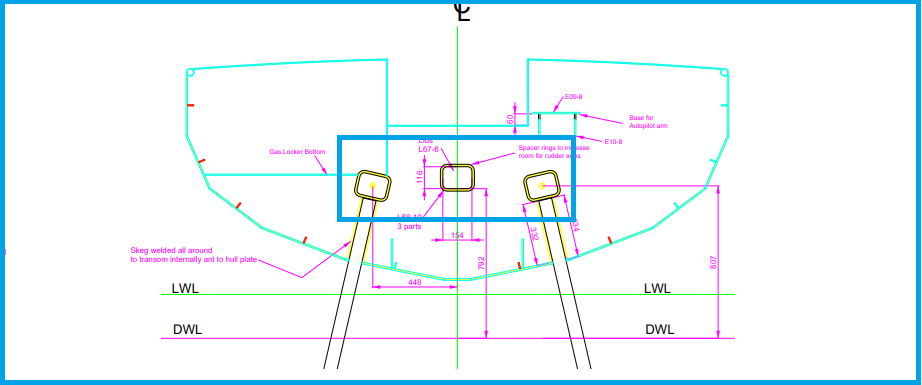

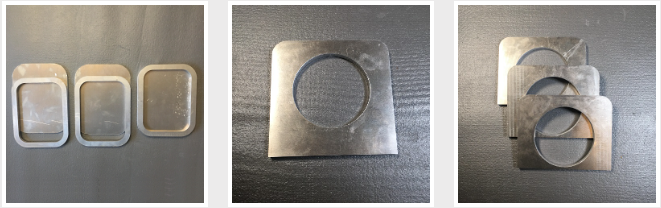

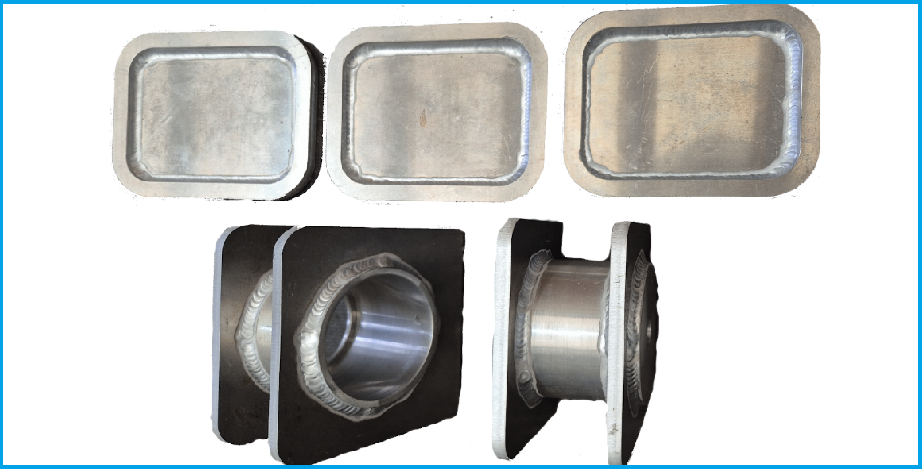

With the Tiller Shaft structure & Bearings assembled the next logical parts to do was the Tiller Shaft brackets that would allow me to attach it all to the transom. In the same process I also created the three ‘Spacers’ needed to prevent the future rudder and tiller clamps to hit the transom due to lack of space during turning.

Bottom left is the spacers before weld to give the extra space that the future tiler and ruder clamps need to swivel freely. Middle piece is the top bracket resting against the deck and holding the tiller shaft top bearing in a fixed place. Bottom right is the three additional brackets used to weld the top and bottom tiller shaft bearings to the transom. Bottom photo is Tiller Shaft, Bearings, Brackets and Spacers assembled.

Cost Tracking

Total Cost Chronological Order:

| 4 | PARTS/MATERIAL | EXTERNAL LABOUR | TOOLS & MISC. | TOTAL |

| (GBP) | £297.42 | £362.94 | £1,857.07 | £2517.43 |

| (USD) | $349.49 | $426.63 | $2,138.47 | $2914.59 |

Breakdown (when applicable):

- Parts/Material – Any raw material that I needed, or any ready made parts.

- External Labour – External help with machining, milling or welding.

- Tools & Misc. – Cost related to project, but not part of physical boat itself.

- Category Breakdown – Cost Tracking per Category in £|$|%.

| PARTS/MATERIAL | (GBP) | (USD) |

| 3 x AL 5083 Spacer Brackets measures (180x140x10mm) – (Material) | £40.20 | (≈$48.16) |

| 3 x AL 5083 (10mm) Spacer Brackets ‘Lids’ measures (180x140x10mm) – (Material) | £14.10 | (≈$17.04) |

| 3 x AL 5083 Round Hole Brackets measures (125x160x10mm) – (Material) | £32.36 | (≈$38.76) |

| 1 x AL 5083 Larger Round Hole Bracket measures (155x160x10mm) – (Material) | £13.18 | (≈$15.79) |

| (Part 4) Tiller Brackets & Spacers | £99.84 | (≈$119.75) |

| EXTERNAL LABOUR | (GBP) | (USD) |

| Laser Cut: 3 x AL 5083 Spacer Brackets measures (180x140x10mm) – (External Labour) | £13.24 | (≈$15.86) |

| Laser Cut: 3 x AL 5083 (10mm) Spacer Brackets ‘Lids’ measures (180x140x10mm) – (External Labour) | £3.24 | (≈$3.92) |

| Laser Cut: 3 x AL 5083 Round Hole Brackets measures (125x160x10mm) – (External Labour) | £8.14 | (≈$9.75) |

| Laser Cut: 1 x AL 5083 Larger Round Hole Bracket measures (155x160x10mm) – (External Labour) | £2.56 | (≈$3.07) |

| 1 x Welding the spacer brackets together – (External Labour) | £25 | (≈$31.30) |

| 1 x Welding the Bracket & Shoes together – (External Labour) | £30 | (≈$38.19) |

| (Part 4) Tiller Brackets & Spacers | £82.18 | (≈$102.09) |

| TOOLS & MISC. | (GBP) | (USD) |

| 4X Ratchet Straps Tie Down 25mm 5 Meters 800KG (temp fixing to wall) | £9.16 | (≈$11.03) |

| (Part 4) Tiller Brackets & Spacers | £9.16 | (≈$11.03 |

| CATEGORY | (GBP) | (USD) | % |

| PARTS/MATERIAL | £99.84 | (≈$119.75) | 75.69% |

| EXTERNAL LABOUR | £82.18 | (≈$102.09) | 17.58% |

| TOOLS & MISC. | £9.16 | (≈$11.03 | 6.73% |

| TOTAL | £191.18 | (≈$232.87) | 100% |

Lessons Learned

Even at the start of this project it is clear that if you have a welder and can weld yourself (rather than using external labour to do this for you) then you can save allot of money in the process. Just for these parts in this chapter 17.58% of the cost is external labour alone (Laser cutting and external welding). In hindsight, the first thing I should have done was to get a welder and learn how to weld. As it stands I will push forward with the plan and get my welder when it is time to start building the actual hull.

- Below some Material/Laser cutting calculations:

£2,109.14 = 45,000.000 mm2 = 45,000 cm2

= 0.047 for 1 x cm2 of 10mm – 5083)

3 x Spacer Brackets measures (180x140x10mm) + 10mm added for sheet & bandsaw cuts = (190x150x10mm)

** 190150=28,500/100=2850.047= 13.40 Each (3 x = £40.20)

3 x Round Hole Brackets measures (125x160x10mm) + 10mm added for sheet & bandsaw cuts = (135x170x10mm)

** 135170=22,950/100=229.50.047= 10.79 Each (3 x = £32.36)

1 x Larger Round Hole Bracket measures (155x160x10mm) + 10mm added for sheet & bandsaw cuts = (165x170x10mm)

** 165170=28,050/100=280.50.047= 13.18 Each

L68-10 (3 Pices) – £44.53 + 20 VAT = £53.44

- Material: 40.20

- Laser Cut: £13.24

E02-10 (3 pieces) – £33.75 + 20 VAT = £40.50

- Material: £32.36

- Laser Cut: £8.14

E03-10 (1 piece) – £13.12 + 20 VAT = £15.74

- Material: £13.18

- Laser Cut: £2.56

Relates Links