Foreword

Welcome to my Kiribati 36 DIY build journey. A 36′ Aluminium ‘Bluewater’ sailboat with twin rudders and a retractable keel. After completing a global circumnavigation on two wheels (See: Blog | YouTube) I now set my sights on doing the same by water. My hope is that the build, cost tracking and lessons learned will aid aspiring boat builders in their own quest. Please know the following:

- I have no affiliation with the company selling the boat plans, in other words, my words are my own. I am however affiliated with Google AdWords in the hope that any revenue made will assist towards the completion of this project.

- In the event of me deviating from the original build plans, adding my own parts, or amending parts then this is highlighted in the articles with ‘** Note‘.

- An up-to-date parts/article Index (including total expenditure) can be found: HERE

- Feel free to ask question via this blog, YouTube comments, or email: kiribati36 @ modularhippo.com – My aim is to respond to all questions within 24 hours.

Cost To Date: £2,547.43->£3,002.11 | $2,952.78->$3,492.44

Index

| Build Progress | Cost Tracking | Lessons Learned | Related Links |

Build Progress

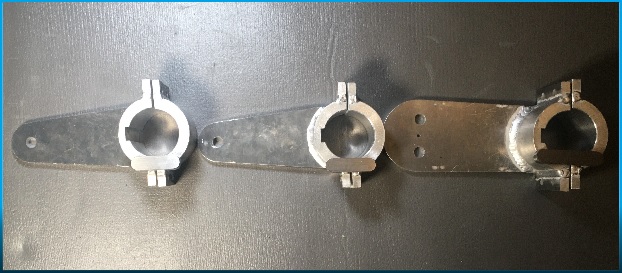

As I now had the spherical link arms I might as well continue with parts related to them. Central & Side Rudder arms would link the arms to the tiller and rudder stocks so seemed to be some good parts to focus on.

M10 SS A4 bolts, nuts, plastic nut caps & spacers to fix the rudder arms to the tiller & rudder stocks once done. Clamps lathed and cut in halves, key-steel trench machined to host the key-steel. Central & side rudder arms together with brackets laser cut and ready for welding assembly:

Cost Tracking

Total Cost Chronological Order:

| 5 | PARTS/MATERIAL | EXTERNAL LABOUR | TOOLS & MISC. | TOTAL |

| (GBP) | £168.20 | £267.80 | £18.68 | £454.68 |

| (USD) | $196.97 | $319.71 | $22.98 | $539.66 |

Breakdown (when applicable):

Parts/Material – Any raw material that I needed, or any ready made parts.

External Labour – External help with machining, milling or welding.

Tools & Misc. – Cost related to project, but not part of physical boat itself.

Category Breakdown – Cost Tracking per Category in £|$|%.

| PARTS/MATERIAL | (GBP) | (USD) |

| 12 x A4 SS Marine Grade 2mm M10 Flat Washers (Parts). | £3.02 | (≈$3.39) |

| 3 x (AL Type: 5083) Central & Side Rudder Arms 12mm Thick (Material) | £41.87 | (≈$49.56) |

| 12 x M10 Stainless Steel A4 Nylon Insert Nut. | £5.65 | (≈$6.34) |

| 24 x M10 Nylon Flat Washer (2mm Thick) – DIN 125A. | £1.45 | (≈$1.63) |

| 24 x White Dome Bolt Nut Plastic Protection Caps Cover | £6.14 | (≈$6.89) |

| 3 x Rudder Arm Clamp Parts AL 6082 T6 Round 240mm (Material) | £54 | (≈$63.93) |

| 12 x M10 A4 Stainless Steel Fully Threaded Bolts | £18.77 | (≈$21.07) |

| 12 x Rudder Arm Brackets (AL Type: 5083) (12mm) – (Material) | £19.24 | (≈$22.78) |

| 3 x Metric Keysteel Bar (20mm X 12mm X 304mm long (12 inches) – (Material) | £18.06 | (≈$21.38) |

| (PART 5) Rudder Arms | £168.20 | (≈$196.97) |

| EXTERNAL LABOUR | (GBP) | (USD) |

| 3 x Laser Cut (AL Type: 5083) Central & Side Rudder Arms 12mm Thick (External Labour) | £11.58 | (≈$13.71) |

| 3 x Rudder Arm Clamp Parts (Lathing/Cutting) – (External Labour) | £80 | (≈$94.70) |

| 12 x Rudder Arm Brackets – Laser Cut (External Labour) | £36.22 | (≈$42.88) |

| 3 x Metric Keysteel Bar (Machining) – (External Labour) | £60 | (≈$71.03) |

| Welding of Brackets, Arms & Clamp Parts (External Labour) | £80 | (≈$97.39) |

| (PART 5) Rudder Arms | £267.80 | (≈$319.71) |

| TOOLS & MISC. | (GBP) | (USD) |

| 16mm HSS Drill | £11.69 | (≈$14.38) |

| 10mm HSS Drill | £6.99 | (≈$8.60) |

| (PART 5) Rudder Arms | £18.68 | (≈$22.98) |

| CATEGORY | (GBP) | (USD) | % |

| PARTS & MATERIAL | £168.20 | (≈$196.97) | 36.99% |

| EXTERNAL LABOUR | £267.80 | (≈$319.71) | 58.90% |

| TOOLS & MISC. | £18.68 | (≈$22.98) | 4.11% |

| TOTAL | £454.68 | (≈$539.66) | 100% |

Lessons Learned

The biggest realization so far is how quickly external costs build up. When romanticizing a build in your head you tend to do quick calculations around material cost & time, but tend to leave out external labour (as you really don’t know what that labour is unless you built a boat before).

Lessons I learnt during this stage:

- Material & External Labour – In the beginning of a project like this it is hard to estimate the ‘hidden’ external labour costs (unless you know exactly what needs doing, how long it will take and know the hourly fees of your machinist/s). As an example, in the creation of the actual complete central & side rudder arms (including nuts & bolts etc.) the cost of was broken in to: Parts/Material (raw material and nuts & bolts) & External Labour (Laser cutting, Machining/Lathing, Welding). In percentage the parts/material stood for 38.58% of the total and External Labour 61.42%. For these particular parts it would not make sense for me to get machines needed to make them myself but for future there is an absolute necessity to save on cost – Note to self, get tools asap to cut down on external costs.

- Tools & Misc.

- Manual Lofting versus Laser Cutting – I had two choices in this area, one being buying sheet aluminium and use lofting calculations to work out final shape and measurements before plasma/bandsaw cut, then finalise with drill, hand and sanding tools. Or as a second choice, order the parts from the local laser cutting company. The local cutting company was a bit reluctant to tell me what they charge for the actual cut (trade secret) so had to do some rough calculations to come up with the number of 20-188% increase on top of material cost. As an example: – At the point of writing this (October 2022) a 12mmx3000x1500mm aluminium sheet of grade: 5083 cost roughly GBP 2,378.25 / (USD 2,670.23) (including of 20%VAT). That is 0.05285 per cm2 for this material type if I buy at mentioned measurements. The biggest of the 3 rudder-arm pieces (Central Rudder Arm) measures 110x240mm + 10mm added for sheet & bandsaw cuts = (120mmx250mm). (12×25=300 x 0.05285 = £15.86) I was charged GBP 20.54 / (USD 23.10) for this part by the laser cutting company (22.8% cost increase). In other words, for this piece I had a choice, make it myself of pay an additional GBP 4.68 / (USD 5.25) to have it cut for me. I also ordered 12 x Rudder arm brackets in the same material (estimated material cost: GBP 19.24 / (USD 21.60), Laser Cut charge for material and cut: GBP 55.46 / USD 62.27) and against the same formula it came in at a 188.25% increase. I believe the large difference in increase 20-188% between the two examples is down to stop/start costs, the more individual pieces the higher the cut fee even if from the same batch. the As much as I would love to make the piece by hand I also have to be realistic and stick to my 5 year building plan, so laser cutting it is. In my final cost calculations I will park this cost under ‘External Labour’.