Foreword

Welcome to my Kiribati 36 DIY build journey. A 36′ Aluminium ‘Bluewater’ sailboat with twin rudders and a retractable keel. After completing a global circumnavigation on two wheels (See: Blog | YouTube) I now set my sights on doing the same by water. My hope is that the build, cost tracking and lessons learned will aid aspiring boat builders in their own quest. Please know the following:

- I have no affiliation with the company selling the boat plans, in other words, my words are my own. I am however affiliated with Google AdWords in the hope that any revenue made will assist towards the completion of this project.

- In the event of me deviating from the original build plans, adding my own parts, or amending parts then this is highlighted in the articles with ‘** Note‘.

- An up-to-date parts/article Index (including total expenditure) can be found: HERE

- Feel free to ask question via this blog, YouTube comments, or email: kiribati36 @ modularhippo.com – My aim is to respond to all questions within 24 hours.

Cost To Date: £6,292.97->£6,666.40 | $7,445.73->$7890.04

Index

| Build Progress | Cost Tracking | Lessons Learned | Related Links |

Build Progress

BLAH BLAH….

Cost Tracking

Total Cost Chronological Order:

| 11 | PARTS/MATERIAL | EXTERNAL LABOUR | TOOLS & MISC. | TOTAL |

| (GBP) | £151.80 | £221.63 | £0 | £373.43 |

| (USD) | $178.20 | $266.11 | $0 | $444.31 |

Breakdown (when applicable):

Parts/Material – Any raw material that I needed, or any ready made parts.

External Labour – External help with machining, milling or welding.

Tools & Misc. – Cost related to project, but not part of physical boat itself.

Category Breakdown – Cost Tracking per Category in £|$|%.

| PARTS/MATERIAL | (GBP) | (USD) |

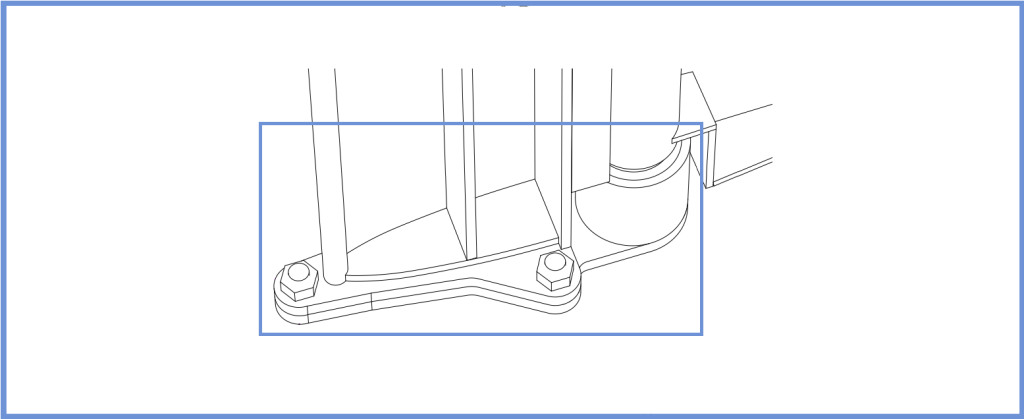

| 6 x M16 SS A4 x 55mm Bolts (Material) | £22.98 | (≈$26.32) |

| 6 x M16 SS A4 Nyloc Nuts (Material) | £9.77 | (≈$11.19) |

| 12 x Plastic M16 Washers (Material) | £4.53 | (≈$5.19) |

| 12 x SS A4 M16 3mm Washers (Material) | £6.94 | (≈$7.95) |

| 12mm | Type: 5083 Aluminium (Material) | £79.32 | (≈$95.02) |

| AL 6082 T6 180 mm Rudder Shoe Cup Rod (Material) | £28.26 | (≈$32.53) |

| (Part 11) | Rudder Shoes | £151.80 | (≈$178.20) |

| EXTERNAL LABOUR | (GBP) | (USD) |

| 12mm | Type: 5083 Aluminium Laser Cut (External Labour) | £16.63 | (≈$19.92) |

| Rudder Shoe Cup Rod Lathing (External Labour) | £50.00 | (≈$57.56) |

| Welding of Shoe Cups and bottom plates (External Labour) | £125.00 | (≈$149.84) |

| Post Adjustments Mel – Rudder shoe Bearings Warped During Weld – (External Labour) | £30.00 | (≈$38.79) |

| (Part 11) | Rudder Shoes | £221.63 | (≈$266.11) |

| CATEGORY | (GBP) | (USD) | % |

| PARTS/MATERIAL | £151.80 | (≈$178.20) | 44.20% |

| EXTERNAL LABOUR | £221.63 | (≈$266.11) | 55.80% |

| TOOLS & MISC. | £0 | (≈$0) | 0% |

| TOTAL | £373.43 | (≈$444.31) | 100% |

Lessons Learned

Lessons I learnt during this stage:

6 x 12mm AL Type: 5083 Aluminium Pieces Laser Cut: £143.45 | (≈$165.15)

Material Meassurements (including 10mm plasma/bandsaw cutting addition)

Big Piece: R11-12 – 150mm x 340mm (160mm x 350mm) = 16×35=560 x 0.05285 = £29.60 x 2 = £59.20

Top Piece: R10-12 – 150mm x 230mm (160mm x 240mm) = 16×25=400 x 0.05285 = £21.14 x 2 = £42.28

Smallest Bottom Piece: 58mm x 270mm (68mm x 280mm) = 6.8×28=190.4 x 0.05285 = £10.06 2 = £20.12

Material Cost: £121.60 | (≈$140.00)

Laser Cut Cost: £21.85 | (≈$25.16)