Foreword

Welcome to my Kiribati 36 DIY build journey. A 36′ Aluminium ‘Bluewater’ sailboat with twin rudders and a retractable keel. After completing a global circumnavigation on two wheels (See: Blog | YouTube) I now set my sights on doing the same by water. My hope is that the build, cost tracking and lessons learned will aid aspiring boat builders in their own quest. Please know the following:

- I have no affiliation with the company selling the boat plans, in other words, my words are my own. I am however affiliated with Google AdWords in the hope that any revenue made will assist towards the completion of this project.

- In the event of me deviating from the original build plans, adding my own parts, or amending parts then this is highlighted in the articles with ‘** Note‘.

- An up-to-date parts/article Index (including total expenditure) can be found: HERE

- Feel free to ask question via this blog, YouTube comments, or email: kiribati36 @ modularhippo.com – My aim is to respond to all questions within 24 hours.

Cost To Date: £1,847.91->£2,071.08 | $2,127.44->$2,384.34

Index

Build Progress

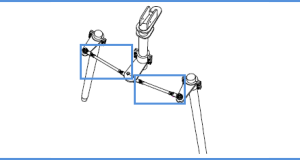

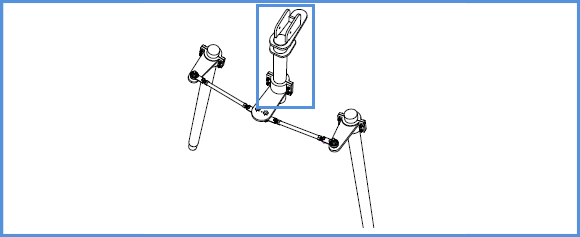

As my plan was to start with all the external parts (before looking at building the actual hull) I thought I start with the ’tiller shaft structure’. With this part complete I could then carry on with other related parts to complete the whole steering mechanism.

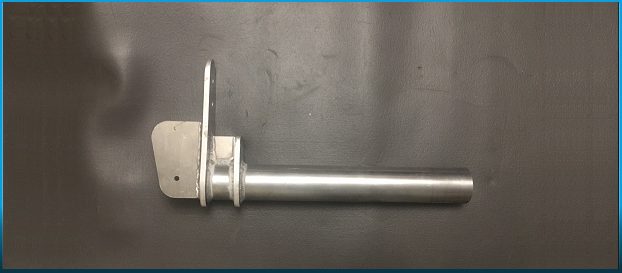

The below top row of pictures show the components that I needed to create the final assembled piece after weld. In picture one you will see a machined rectangular cut-out to cater for the ‘keysteel’ that will hold the rudder side arm clamps in place ‘(PART 5) Rudder Arms‘. Picture two is the laser-cut parts that forms the attachment point of the actual tiller. Picture three is a radius (Sphere: Radius 73 | Diameter 146) to the bottom of the tiller shaft to decrease friction when resting in contact with tiller bearings ‘(Part 3) | Tiller Bearings‘. ** Note: the radius was not part of the original plans but discusses with designed who saw no harm in my alteration. Final part assembled and welded in bottom image.

Cost Tracking

Total Cost Chronological Order:

| 2 | PARTS/MATERIAL | EXTERNAL LABOUR | TOOLS & MISC. | TOTAL |

| (GBP) | £99.08 | £124.09 | £1,847.91 | £2,071.08 |

| (USD) | (≈$113.83) | (≈$143.07) | (≈$2,127.44) | (≈$2,384.34) |

Breakdown (when applicable):

- Parts/Material – Any raw material that I needed, or any ready made parts.

- External Labour – External help with machining, milling or welding.

- Tools & Misc. – Cost related to project, but not part of physical boat itself.

- Category Breakdown – Cost Tracking per Category in £|$|%.

| PARTS/MATERIAL | (GBP) | (USD) |

| Tiller Rudder Shaft – Aluminium Round Bar 2 3/4″ x 517.0mm – 6082 T6 (Material) | £57.60 | (≈$66.42) |

| 6 x Tiller Holder Construction – Aluminium (10mm AL Type: 5083) (Material) | £41.48 | (≈$47.71) |

| (Part 2) | Tiller Shaft Structure | £99.08 | (≈$113.83) |

| EXTERNAL LABOUR | (GBP) | (USD) |

| Keysteel Machining (External Labour) | £15 | (≈$17.30) |

| 6 x Tiller Holder Construction Laser Cuts (External Labour) | £9.09 | (≈$10.45) |

| Tiller Holder Construction Welding (External Labour) | £100 | (≈$115.32) |

| (Part 2) | Tiller Shaft Structure | £124.09 | (≈$143.07) |

| CATEGORY BREAKDOWN | (GBP) | (USD) | % |

| PARTS/MATERIAL | £99.08 | (≈$113.83) | 44.40% |

| EXTERNAL LABOUR | £124.09 | (≈$143.07) | 55.60% |

| TOOLS & MISC. | £0 | (≈$0) | 0% |

| TOTAL | £223.17 | (≈$256.90) | 100% |

Lessons Learned

Lessons I learnt during this stage:

- Laser cut parts comes with one side having a sharp edge. To make parts more pleasant to work with before assembly you can use Metal Deburring Tool tool to easily remove the sharp edges.

- My Local laser cutting company charged me £50.57 (Inc. VAT) for the 6 parts. If I would have bought the material for it in sheet form I would have paid: £41.48 (I am sure the Laser cutting company have way better prices then me but that is what I would have paid as a small-order end user). This equates to a 21.91% increase in cost (in other words, I paid £9.09 to have the parts cut compared to buying the material and shaping the pieces myself)

Calculation:

At the point of writing this (November 2022) a 10mmx3000x1500mm aluminium sheet of grade: 5083 cost roughly GBP 2,109.14 / (USD 2,425.72) (including of 20%VAT) if bought from (https://lakelandsteel.uk). That is 0.04686 per cm2 for this material type if I buy at mentioned measurements.

cm2 square measurements (10 mm added horizontally/Vertically to cover sheet plasma cutting and band saw fine cuts):

Small Square 35x52mm |45×62 | 4.5×6.2 = 29.9 x 0.04686 = £ 1.40

Big Square 50x51mm | 60×61 | 6.0×6.1 = 36.6 x 0.04686 = £1.72

Leftw Wall 140x95mm | 150×105 | 15.0×10.05 = 150.75 x 0.04686 = £7.06

Right Wall 140x95mm |150×105 | 15.0×10.05 = 150.75 x 0.04686 = = £7.06

Upper Plate 110x280mm | 120×290 | 12.0×29.0 = 348 x 0.04686 = £16.31

Lower Plate 110x131mm |120×141 | 12.0×14.1 = 169.2 x 0.04686 = £7.93

Paid: £41.48

Small Square = 1.79

Big Square E06-10 = 2.19

2 x Wall E08-10 = 13.73

Upper Plate E04-10 = 15.81

Lower Plate E05-10 = 8.62

Total: £42.14 x 20% VAT = £50.57

Material Cost: £41.48

Cut cost: £9.09

Related Links

Quick links that I have come across during build that might be of use: