Build Plans Available Here: https://bgyachtdesign.com

Foreword

Welcome to my Kiribati 36 DIY build journey. A 36′ Aluminium ‘Bluewater’ sailboat with twin rudders and a retractable keel. After completing a global circumnavigation on two wheels (See: Blog | YouTube) I now set my sights on doing the same by water. My hope is that the build, cost tracking and lessons learned will aid aspiring boat builders in their own quest. Please know the following:

- I have no affiliation with the company selling the boat plans, in other words, my words are my own. I am however affiliated with Google AdWords in the hope that any revenue made will assist towards the completion of this project.

- In the event of me deviating from the original build plans, adding my own parts, or amending parts then this is highlighted in the articles with ‘** Note‘.

- An up-to-date parts/article Index (including total expenditure) can be found: HERE

- Feel free to ask question via this blog, YouTube comments, or email: kiribati36 @ modularhippo.com – My aim is to respond to all questions within 24 hours.

Cost To Date: £11,474.53->£11,537.03 | $14,046.39->$14,155.09

Index

| Build Progress | Cost Tracking | Lessons Learned | Related Links |

Build Progress

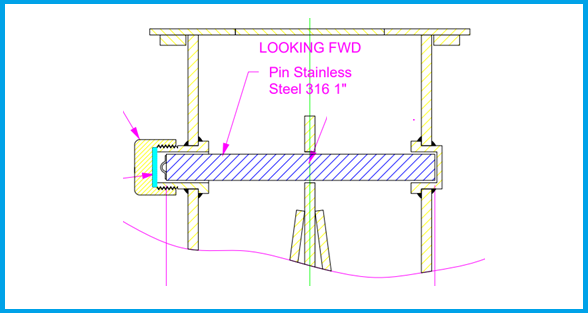

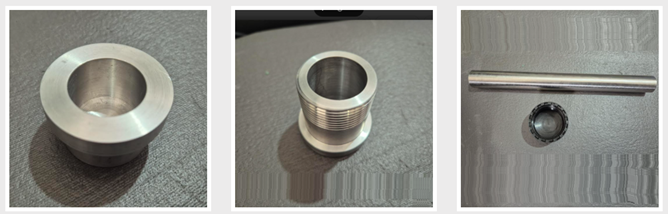

I had now reached a stage where it was time to start adding all the little mechanical parts that was part of the keel box. The Keel Lock Up Pin felt like a good place to start. In short, this is just 4 parts that allow me to ‘fix’ the keel in it’s upright position once retracted (instead of just hanging unsecured by the spectra ropes). A pin that goes through a hole at the bottom of the keel and is supported by two end caps penetrating the keel box wall and welded in to position. One cap has a closed end and the other threaded so once pin is inserted a lose cap can be screwed tight to keep pin in place:

Progress:

Total Cost Chronological Order:

| 17 | PARTS/MATERIAL | EXTERNAL LABOUR | TOOLS & MISC. | TOTAL |

| (GBP) | £22.50 | £40.00 | £0.00 | £62.50 |

| (USD) | (≈$54.92) | (≈$53.78) | (≈$0.00) | (≈$108.70) |

Breakdown (when applicable):

Parts/Material – Any raw material that I needed, or any ready made parts.

External Labour – External help with machining, milling or welding.

Tools & Misc. – Cost related to project, but not part of physical boat itself.

Category Breakdown – Cost Tracking per Category in £|$|%.

| PARTS/MATERIAL | (GBP) | (USD) |

| 1 x Stainless Steel Round Bar 1″ x 260.0mm (lock up Pin) | £18.36 | (≈$24.68) |

| 1 x Aluminium Round Bar 2″ x 120.0mm 6082 T6511 (Threaded End & Blind End) | £15.60 | (≈$20.97) |

| 1 x 1-1/4 Plastic Threaded PVC Cap | £6.90 | (≈$9.27) |

| (Part 17) | Keel Lock Up Pin | £22.50 | (≈$54.92) |

| EXTERNAL LABOUR | (GBP) | (USD) |

| 1 x (Threaded End & Blind End) Lathing Mel – (External Labour) | £40.00 | (≈$53.78) |

| (Part 17) | Keel Lock Up Pin | £40.00 | (≈$53.78) |

| CATEGORY | (GBP) | (USD) | % |

| Parts/Material | £22.50 | (≈$54.92) | 36.00% |

| External Labour | £40.00 | (≈$53.78) | 64.00% |

| Tools & Misc. | £0.00 | (≈$0.00) | 0.00% |

| TOTAL | £62.50 | £108.70 | 100% |

Lessons Learned

If any then it would be that some parts are better of being sub-contracted, especially if you have limited time to be hands on. For the low cost to have the end caps made it made more sense to have a third party person doing this for me while I was pushing forward in other areas.